Introduction

It's assumed that you're building a kit from Filastruder, and you've completed all previous sections. At the end of this section you should have a "top extrusions" assembly together for your RailCore frame.

-

-

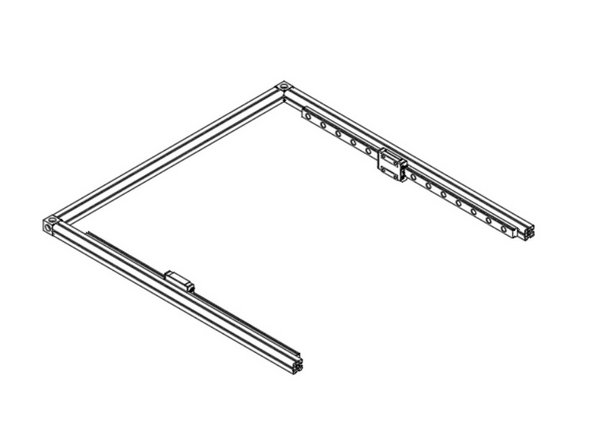

Lay Out Top Extrusions as pictured

-

The kit includes (2) untapped 425mm extrusions - for this step be sure to use the tapped extrusions.

-

It can be helpful to use masking tape to add a label to the top of each extrusion indicating which it is (Top Back, Top Left, etc)

-

Be sure the Corner cubes have a larger hole facing up, smaller hole facing down.

-

-

-

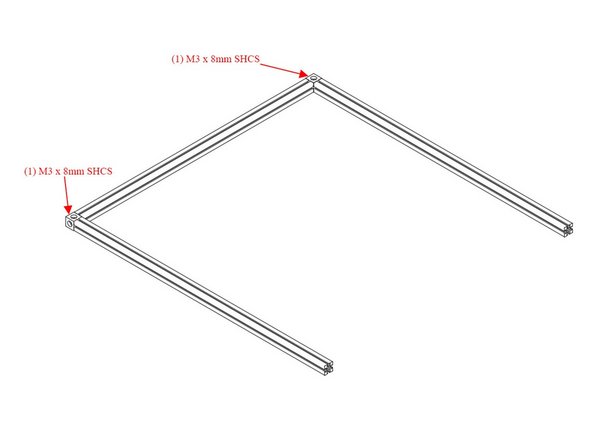

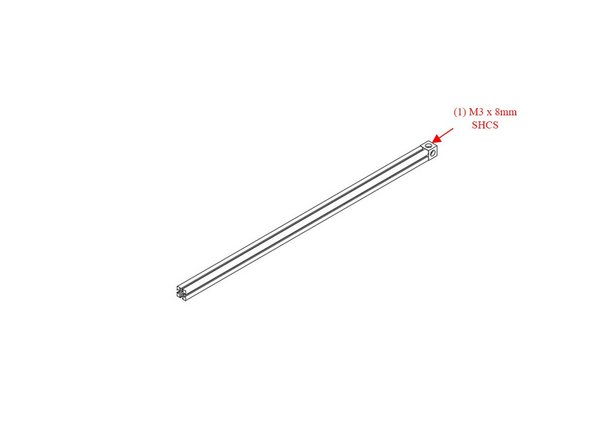

Bolt Corner Cube to Top Left 425mm Extrusion using (1) M3 x 8mm Socket Head Cap Screw

-

Note on the corner cube, the small hole is pointing to the right in this image

-

-

-

Hold the Extrusion as it will be oriented on the printer (make sure the big hole on the corner cube faces up)

-

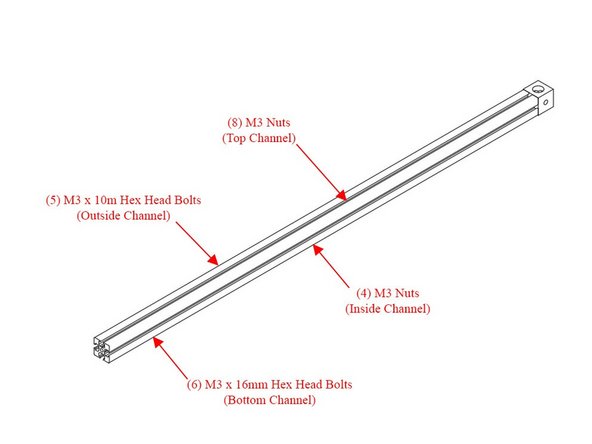

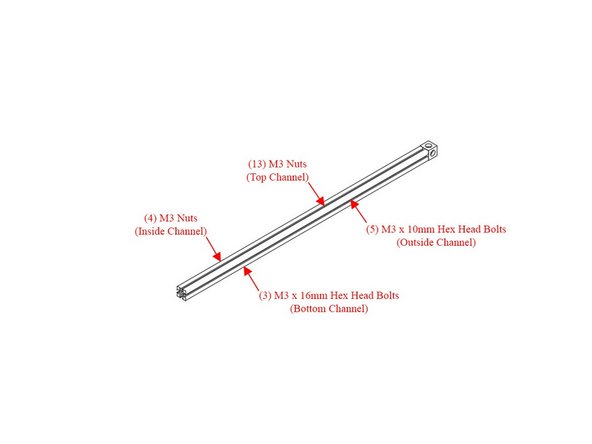

Slide (8) M3 nuts into the top channel (If you're installing a halo, add 6 additional M3 nuts for a total of 14)

-

Slide (5) M3 x 10mm Hex Head Bolts in the outside channel

-

Slide (4) M3 nuts in the inside channel

-

Slide (6) M3 x 16mm Hex Head bolts in the bottom channel

-

Note on the corner cube, the small hole is pointing to the right in this image

-

-

-

Attach Second Corner Cube to Top Left Extrusion using (1) M3 x 8mm socket cap head screw. Be sure the large hole is up, small hole is down.

-

Note on both corner cubes, the small hole is pointing to the right in this image

-

-

-

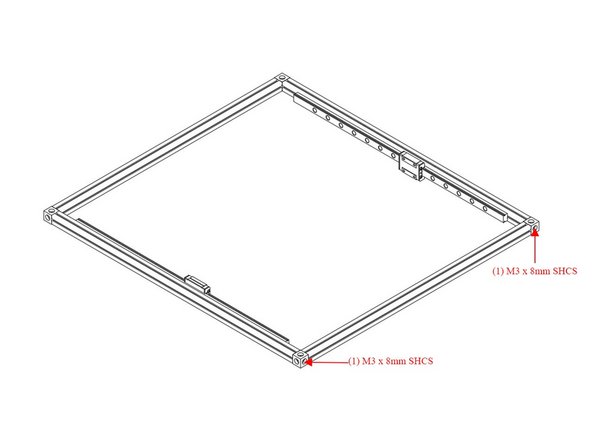

Attach the (2) 460mm Top Front and Top Back Extrusions using (1) M3 x 8mm socket cap head screw each.

-

-

-

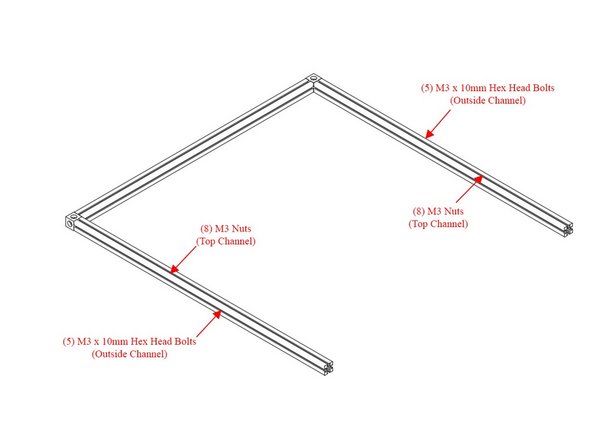

(5) M3 x 10mm Hex head bolts go in the outside channel of the back extrusion.

-

(8) M3 nuts go in the top channel of the back extrusion (if installing the optional Halo, add six (6) more nuts in this channel for a total of 14).

-

(8) M3 nuts go in the top channel of the front extrusion (if installing the optional Halo, add six (6) more nuts in this channel for a total of 14).

-

(5) M3 x 10mm Hex Head Bolts go in the outside channel of the front extrusion.

-

-

-

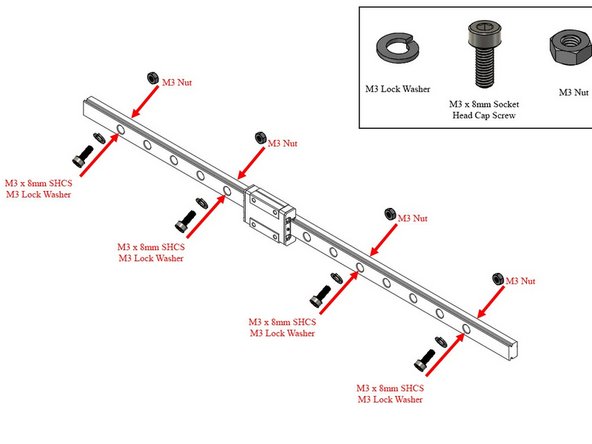

Use a bit of masking tape to keep your carriage from sliding off your linear rail.

-

Select 4 evenly spaced holes in your linear rail. (roughly 3 empty holes between each bolt)

-

Place a lock washer on (1) M3 x 8mm socket cap head screw, and place it into one of the holes selected. Loosely thread on (1) M3 nut to the bolt. DO NOT TIGHTEN THEM FULLY. The M3 nut only needs to be threaded onto the tip of the bolt, you want a gap between the nut and the back of the rail. Repeat for the other three (3) holes.

-

Repeat the above steps for the other 400mm rail.

-

It is highly recommended to use a bit of masking tape to keep the carriage from sliding off of the linear rail.

-

-

-

Attach Linear rail to Top Front and Top Back Extrusions by sliding the M3 nuts into the inside channel on the extrusion.

-

Roughly center the extrusion, and then snug up the bolts.

-

Do not overtighten the bolts, you just need them snug for now. They'll be tightened later.

-

It is highly recommended to use a bit of masking tape to keep the carriage from sliding off of the linear rail.

-

-

-

Set aside the rest of your top extrusion assembly for now, so we can work on the top right extrusion.

-

Attach a corner cube to the right 425mm extrusion using (1) M3 x 8mm socket cap head screw.

-

-

-

Slide (13) M3 nuts into the top channel (if installing the optional Halo, add six (6) more nuts in this channel for a total of 19)

-

Slide (4) M3 nuts into the inside channel

-

Slide (5) M3 x 10mm Hex Head Bolts into the outside channel

-

Slide (3) M3 x 16mm Hex Head Bolts into the bottom channel

-

Be sure the orientation of the corner cube is correct. A large hole should face up, a small hole should be facing down, and a small hole should be facing towards the inside channel

-

-

-

Attach Second Corner Cube to Top Right Extrusion using (1) M3 x 8mm socket cap head screw.

-

-

-

Attach Top Right Extrusion to the rest of the Top Extrusion Assembly using (2) M3 x 8mm socket cap head screws.

-

Cancel: I did not complete this guide.

33 other people completed this guide.