-

-

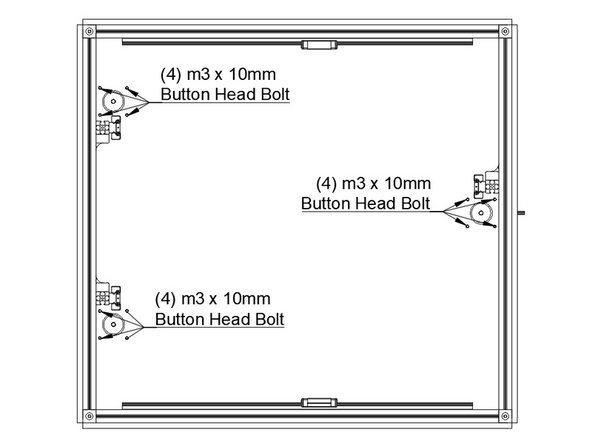

Install the (3) 1.8 degree Z steppers into the bottom panel using (4) M3 x 10mm button head bolts per stepper. The connectors should point towards the right side of the printer.

-

It's important the Z towers are positioned on the correct side of the steppers, as is shown in the picture.

-

-

-

Skip this step if using an aluminum base plate

-

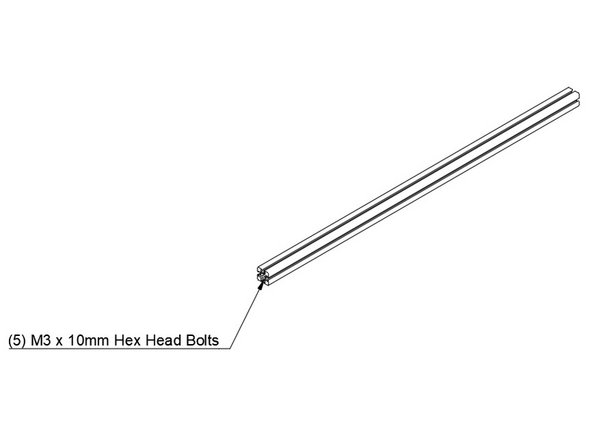

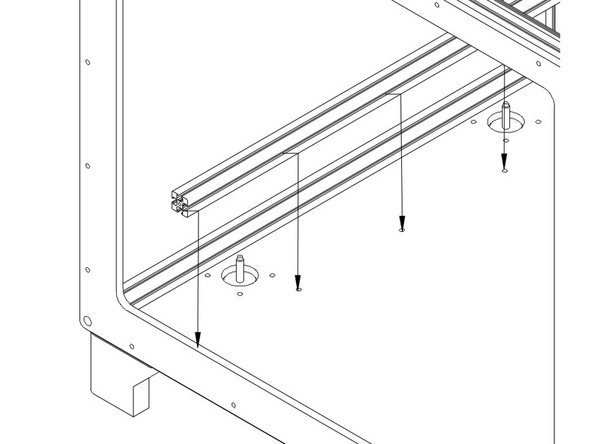

Insert (5) M3 x 10mm Hex Head Bolts into the bottom channel of one of the remaining 425mm Extrusions.

-

Lower the extrusion to the bottom panel so the bolts go through the 5 holes that go front to back in the panel, near the left side steppers.

-

Secure the bottom panel brace using (5) M3 washers and (5) M3 nuts on the bottom side of the printer.

-

Repeat this process for the brace on the right side of the bottom panel.

-

-

-

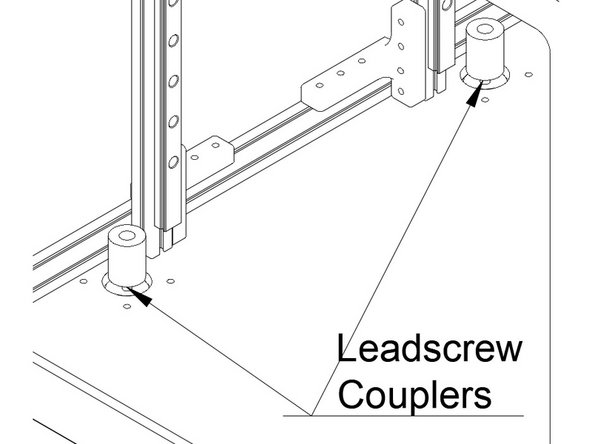

Install the (3) Leadscrew couplers onto the Z stepper shafts. The couplers should be fully seated and tightened.

-

The Couplers are silver, with colored plastic combining the two halves.

-

The third stepper on the right side of the printer is not pictured.

-

-

-

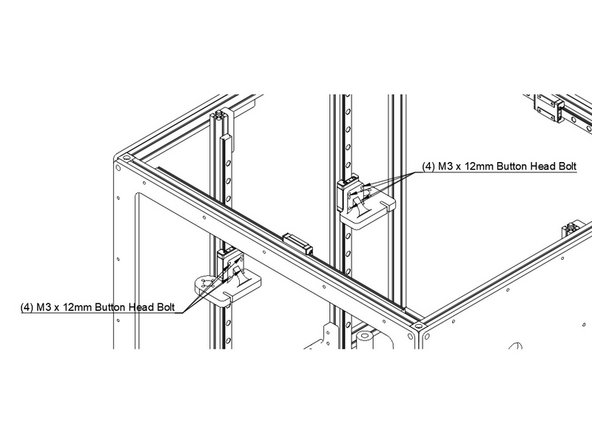

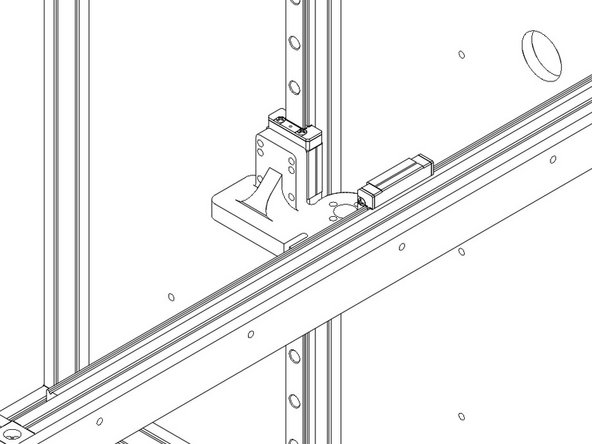

Install the (3) Z Yokes onto the Z carriages using (4) M3 x 12mm Button Head Bolts each. Note the orientation of the yokes in the pictures - ensure the hole for the leadscrew lines up over the stepper.

-

For Misumi linear rails, use M3 x 10mm instead of M3 x 12mm bolts.

-

-

-

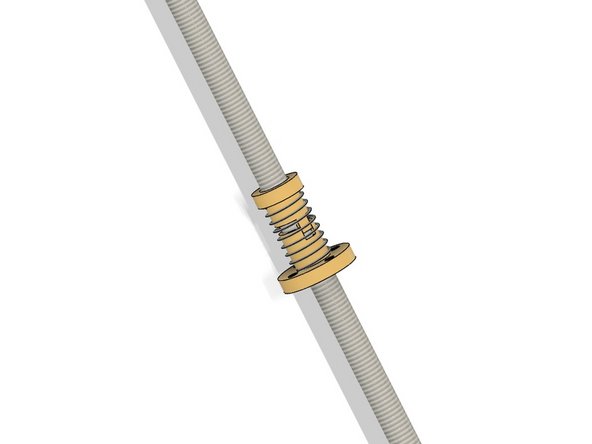

Prepare the anti-backlash nut for mounting onto the leadscrew.

-

Thread the bottom half (with the flange) down onto the screw until just the teeth are sticking up past the end of the leadscrew.

-

Put the spring on the bottom of the leadscrew nut and hold it there until the next step.

-

Insert the top of the leadscrew nut, pushing down until the teeth in the upper and lower parts interlock.

-

Thread the nut assembly onto the leadscrew, until it's about 1/3 of the way down.

-

Repeat the above steps for the other (2) leadscrews.

-

-

-

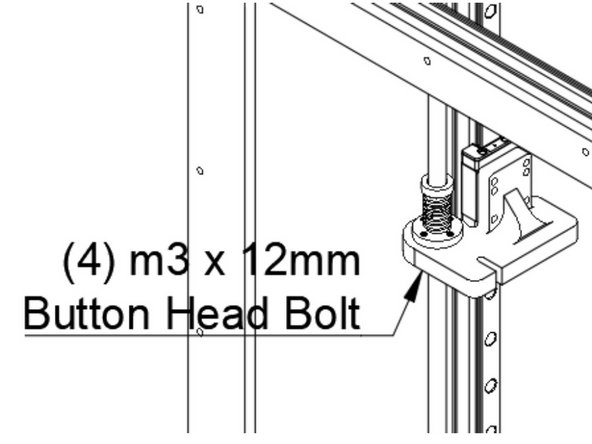

Insert the leadscrew down through the hole in the yoke, and into the leadscrew coupler.

-

You may need to slide the Z tower around to line it up so you can get the leadscrew into the coupler.

-

Tighten the grub screw in the coupler.

-

Insert (4) M3 x 12mm Button head bolts through the bottom of the yokes, and into the holes on the leadscrew nut flange. Do not overtighten, you can strip the Delrin.

-