Introduction

It's assumed that you're building a kit from Filastruder, and you've completed all previous sections. At the end of this section you should have your Z axis attached to your frame assembly.

-

-

Each Z bracket is installed using (3) m3 Nylock Nuts.

-

Note the orientation of each bracket. It is CRITICAL that the brackets all face the correct way.

-

On the left, the long horizontal ends of the brackets point towards each other. The vertical ends of the brackets face out towards the front and back of the frame

-

On the right the vertical ends of the brackets face the front of the frame.

-

-

-

Put a m3 x 16mm hex head bolt through each Z Bracket and attach it loosely with an m3 nut. Only thread the nut on loosely. Each bracket gets (4) m3 x 16mm hex head bolts.

-

Repeat this process for all (6) Z brackets.

-

-

-

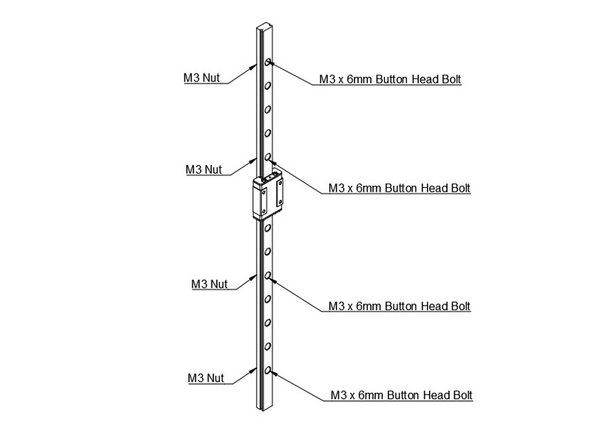

Prep the Z axis mgn12 linear rails in the same fashion as for the X axis rails.

-

Select 4 evenly spaced holes in the rail. Place a lock washer on (1) m3 x 8mm button head bolt, and place it into the Loosely thread on (1) m3 nut to the bolt.

-

For the ZLT you should use (8) bolts spaced evenly, instead of (4) per rail.

-

Repeat for all (3) Z linear rails.

-

It is highly recommended to use a bit of masking tape to keep the carriage from sliding off of the linear rail.

-

Kits shipping after 5/12/20 include lock washers to go on these bolts, not yet pictured. Place on the bolt before inserting in the rail.

-

-

-

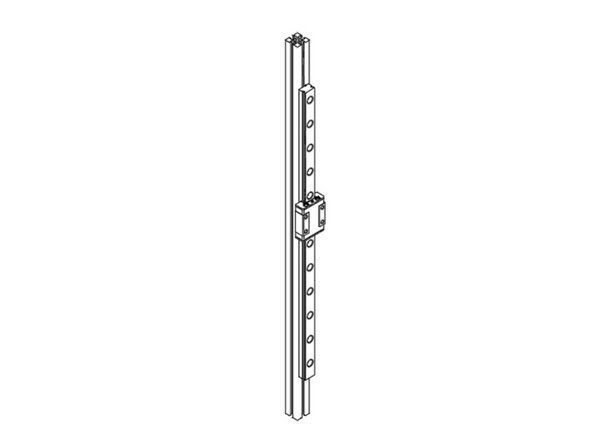

Slide the linear rails onto the (3) 445mm Z extrusions, and snug up the bolts (do not overtighten them.

-

It is highly recommended to use a bit of masking tape to keep the carriage from sliding off of the linear rail.

-

-

-

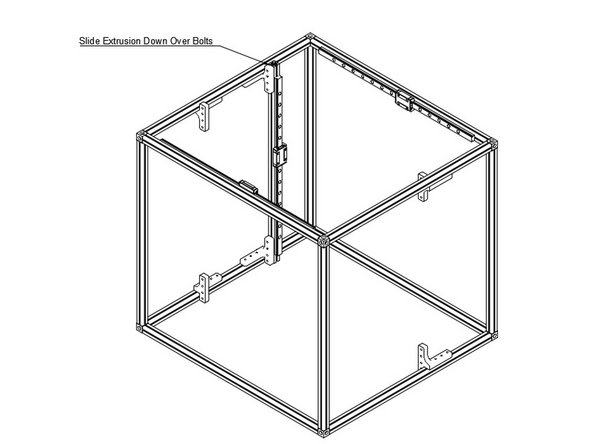

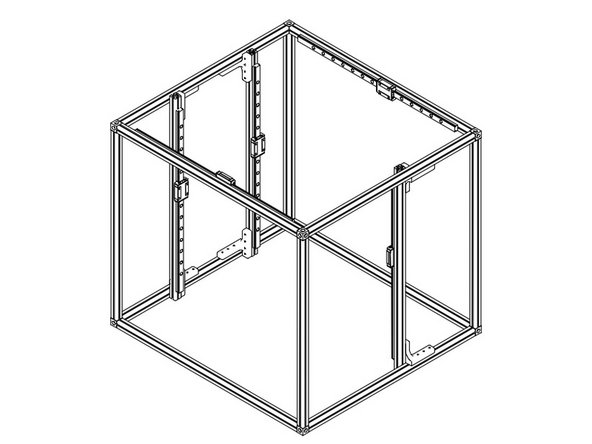

Take your Z extrusion with a linear rail attached, and slide it down onto the hex head bolts you added earlier on the Z brackets.

-

The extrusion should attach to all 4 bolts on both the top & bottom Z brackets.

-

Tighten down the nylock nuts to hold the Z extrusions in place.

-

Repeat for all 3 Z extrusions.

-